Menu

Four projects in one with a single purpose: generate green energy and local wealth.

The Green Oak This is the most advanced Project Finance and a benchmark for the sector in Europe.

annual green e-methanol (RFNBO).

Green H2 produced and consumed at the e-methanol plant per year.

Biogenic CO2 produced and captured in the plant per year.

Renewable electricity generation per year-

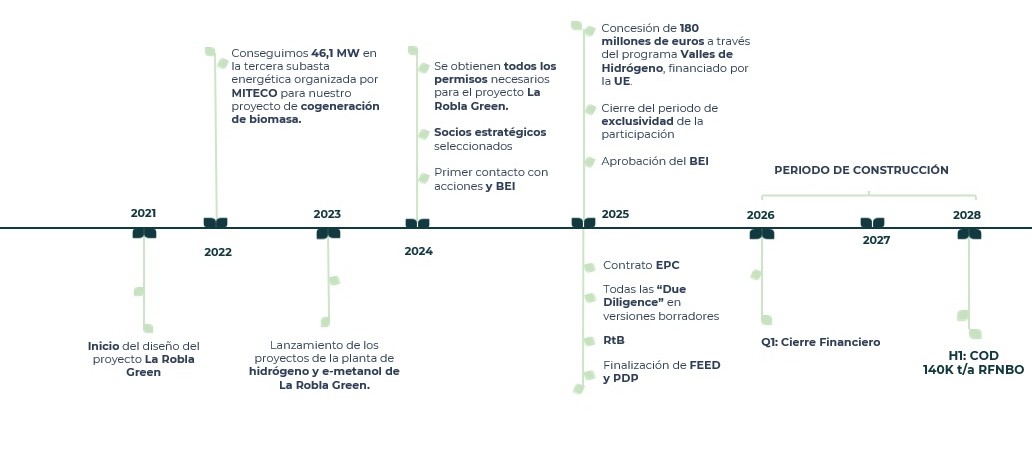

In 2022, Reolum was awarded 46.1MW of renewable energy for biomass in the third energy auction called by MITECO.

This was the beginning of the consolidation of a project never before seen at the European level, whose objective was to improve the efficiency of one of the Just Transition territories.

.

Our proposal consists of a biomass plant with a power output of 49.9MW and an annual electricity production of 370 GWh on the grounds of the former La Robla coal-fired power plant.

In parallel, it generates a synergistic auxiliary network of an industrial and service nature, bringing back to the area an activity that did not exist until now.

The production of the facilities is generated through some 315,050 tons of biomass which, additionally, will provide greater stability to the electrical system of the area.

The La Robla Green biomass cogeneration plant is a renewable energy source derived from the controlled combustion of organic agricultural waste. This waste currently has no use.

Corn waste that was previously burned or left to decompose, releasing emissions into the atmosphere, now feeds the biomass plant, and the resulting CO2, instead of being released into the atmosphere, is converted into raw material thanks to the carbon capture plant. 200,000 tons annually will be transported to the green e-methanol plant for production.

Reolum was selected to lead the "Leonese Valley of Green Hydrogen" project, becoming a beneficiary of the MITECO H2 Valleys program. La Robla Green received an allocation of €180 million.

This means that the electricity used during the process comes from renewable sources.

This green hydrogen will meet the requirements imposed by European regulations to be considered RFNBO

All green hydrogen production will be used as a supply for the e-methanol plant.

For his part, green e-methanol It is produced using hydrogen from water electrolysis in a plant powered by renewable electricity and biogenic CO2. It is a highly demanded, and scarce, biofuel, primarily in industrial settings:

He e-methanol It has become a key energy vector for compliance with new European regulations in the sectors maritime, aeronautical and in the transposition of the RED III Directive.

Its renewable nature and its capacity to significantly reduce greenhouse gas emissions position it as one of the

More viable solutions for decarbonizing heavy transport. In aviation and maritime transport, where direct electrification is limited, e-methanol makes it possible to meet the mandatory carbon reduction targets and the progressive increase in sustainable fuels required by the EU.

In turn, RED III establishes strict thresholds for renewable energy in fuels and industrial processes, requirements that e-methanol meets thanks to its renewable origin and its certifiability under schemes such as RFNBO.

In this way, it becomes a strategic pillar for moving towards cleaner, more competitive transport that is aligned with the European energy transition.